DISCOVER THE RHINO DIFFERENCE.

GET A QUOTE.

The RHINO Steel Building Difference

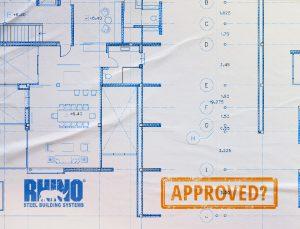

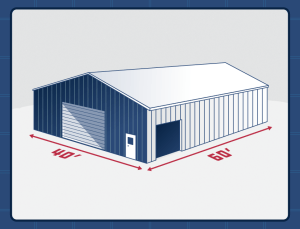

Not all steel building companies are alike. Our exceptional prefabricated steel buildings and first-rate customer service set us apart from the common herd. It’s what we call The RHINO Difference.

RHINO Steel Buildings are engineered to be:

STRONGER

MORE VERSATILE

EASIER TO BUILD

THE RHINO STEEL BUILDING BLOG

![]()

CHAT WITH US

Our staff knows a thing or two about metal buildings. We’ll help you find exactly what you’re looking for.

![]()

TAKE A BROCHURE

Read more about RHINO’s features, accessories, insulation options, and first-rate customer support.

![]()

Qualified Builders Program

Are you a builder or concrete service provider with a stellar reputation and commitment to high standards? Apply for our Qualified Builders Program and allow us to recommend your services to our customers around the country.